There are too many stories of oil drain bolts breaking or flash sockets being over-tightened, all because someone was at work on a dirt bike without a torque wrench. But I’m not telling you something you don’t previously discern. Underneath is our best torque wrench for dirt bike maintenance. Though I wish there were a one-size-fits-all torque wrench, there isn’t. Selecting a torque wrench centered on what you want or strategy for using it is the best tactic. You’d have two or three diverse torque wrenches in a seamless world. I’ll describe.

Instructions for Keeping Your Torque Wrench

Every torque wrench requires to be regulated occasionally to be seamlessly correct. That’s why I like the Bike Master; it delivers a stress-free way for this to be completed. Be vigilant not to drip or crash a torque wrench on things; otherwise, it can become erroneous. Hoard the torque wrench in its box to defend it. Never use a torque wrench to untighten a rod. Use it only for jerking and when you need a correct torque locale. Otherwise, use an unvarying wrench.

What Are Torque Wrenches?

Torque wrenches are essential gears when it comes to dirt bike upkeep. Make sure you possess a high-quality torque wrench if you need to dress your dirt bike upkeep yourself. A high-end torque wrench that we endorse is the Park Tool Ratcheting Torque Wrench TW-5.2. It is perfect for mutual and more significant works, including seat-posts and handlebars, seamlessly custom-made for dirt bikes. You will have to use a minute of additional money, but it will make your dirt bike upkeep stress-free, stirring poise and getting the job done.

Don’t surplus money or other high-end torque wrenches; they typically aren’t intended for dirt bikes. This will cost the money you use on it.

Different Kinds of Torque Wrenches

You will discover an extensive range of torque wrenches on the marketplace, each with its benefits and drawbacks. Here is a guide to a few of them.

1. Click Wrench

This is a very beneficial wrench, allowing users to attain the appropriate torque setting. When the correct setting is extended, the wrench twitches, gliding, stopping the overtightening of screws.

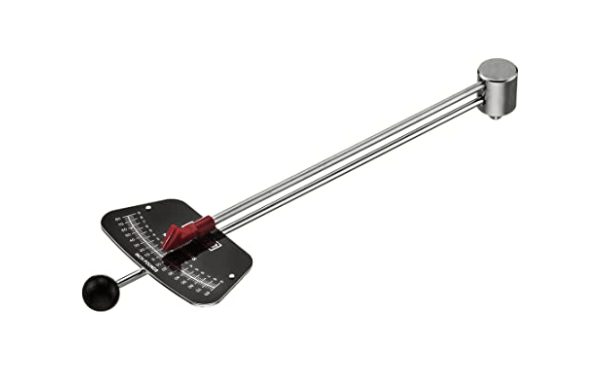

2. Beam and Pointer Torque Wrenches

These torque wrenches are inexpensive and accessible in the marketplace. They own a small scale and an indicator, like one of those old bathroom gauges. Unfortunately, they are inexpensive for a cause, are vulnerable to being determined simply, and often display erroneous appraisals. Their wrongness is predominant even in torque settings that are agiler.

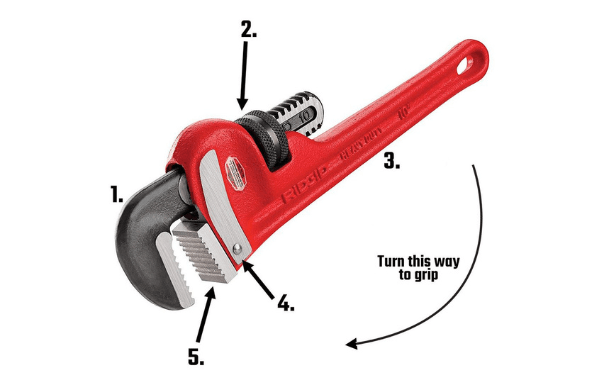

3. Plumber’s Wrench

This is like the click wrench in that it slides upon getting the ideal torque setting. In addition, though, it comes with a T-shaped lever.

4. Hydraulic Torque Wrench

This torque wrench is motor-powered, and most frequently used for motorized. It’s usually seen in competing quarries.

5. Deflecting Beam Wrench

These torque wrenches don’t relate torque to a looping spiral, relating it in its place to a bouncing beam.

So is It Worth Buying A Torque Wrench?

You need a torque wrench if you plot to do any significant work on your engine or some chief powertrain gears. For example, Overtightening cylinder-head rods can cause exclusive injury and disastrous coolant harm. Likewise, a too-tight drain with multiple screws can cause the manifold to bang.

Things You Must Consider Before Buying Your Torque Wrench For Dirt Bikes

How tough can it be to purchase a wrench?” it is something that marks everybody’s attention. Well, fairly, it is riskier than you consider. There are so many features you do not understand, but you must deliberate them before getting yourself the best torque wrench for your dirt bikes.

For example, in terms of enterprises, every brand bids on a series of structures. How would you choose without deliberating everything? That is why we are here to support you. All the powerful fundamentals unfavorably connected to torque wrenches you must reflect on before buying is stated below.

1) Two Are Always Better

Buying a sole wrench that contracts with an explicit variety of nuts and screws will not be capable of getting its grippers on all of the bolts. For example, the bolts on the engine zone need a smaller force range, while the bolts on the wheel area want a wrench shielding a more significant part. If you attempt to use the same tool on every screw, they will instantly halt off. Thus, if you can have enough money, it is always better to get more than one to report both the minor and advanced ranges of torques.

2) An Reasonable Choice

Attaining more than one tool is not a reasonable choice. So, what to do when you have a preliminary financial plan? The answer is clear. The bulk of nuts and screws on a dirt bike are the ones that do not need much power to fit. In other words, the wrench with 2 to 25 Nm force can switch the most work you might face during the upkeep. But still, it is a dangerous hazard, and you’d have to pay visits to a garage if something cracked off, expending the same wrench far and wide.

3) Mechanical Vs The Digital Wrenches

When it comes to buying the instrument, the most mutual impasse you might discover is which one to purchase: the motorized one or the cardinal one. Let’s put some light upon their pros and scams one by one. Both are similarly appropriate if we talk about the correctness of motorized work. The correctness typically depends on user input. To some extent, digital wrenches are improving because of additional features such as pointers.

When it comes to mounting settings, the motorized wrenches have a modest, predictable scale that you can fix by hand. On the other hand, the digital ones have innovative structures in this area. The scale is set through a digital spectacle that identifies the requisite torque.

Read Also: Important Dirt Bike Tools For All

How Inspiring Is That?

Furthermore, in terms of trustworthiness, motorized wrenches triumph over digital ones. The reason is its plainness. They will assist you for an extended time. But with the up-to-date wrenches, you get entrance to numerous modern structures, counting pointers, digital presentation, shaking settings, and other radars. But one thing goes without saying, the more features the wrench delivers, the more expensive it is. Thus, motorized ones are improved in terms of affordability.

With all this data, now, you’d be able to make a fully informed decision.

4) Accessibility Of A Back-Lit Display

If you have selected to go with the ordinal wrench, then make certain that it has a backlit feature. Controlling a torch along with any other device would be excessively bothersome. You must have a well-lit working room to protect yourself from hitting your tool in the wrong place. So, working in a blurred garage, at night, or in a shutdown, an enlightening wrench will undoubtedly come in convenient.

5) Variety Of Torque Items

There are numerous computing components used in diverse types all around the world. The units must tie. Otherwise, it would all be useless. Furthermore, it is always better to go for a tool with more than one-unit locale. So, you wouldn’t fear altering your instrument kit along with your dirt bike. The digital wrenches have a more significant number of units, so they are purely a better choice in this case.

Is Digital Torque Wrench Better?

Digital torque wrenches have a big benefit over other kinds of torque wrenches regarding their scale dependability because they have noticeable displays that show the present torque interpretation.

What Kind Of Torque Wrench Is Most Perfect?

Dial-type torque wrenches are usually one of the correct kinds of torque wrenches. The dial-type wrench is the only torque wrench where the hand-hold position on the wrench does not simply exaggerate the closing reading.

How Long Do Torque Wrenches Last?

Approximately 12 months. Depending on usage, but usually every 12 months or 5,000 cycles. We commonly see 20-year-old torque wrenches that are still precise.

How Often Does A Torque Wrench Must Be Regulated?

Twelve months as a universal rule of thumb, it’s astute to test the standardization of your torque gears every six months or twelve months. That’s exceptional enough that it doesn’t obstruct efficiency and often enough that it doesn’t generate indecent charges.

Do All Torque Wrenches Need To Be Regulated?

A torque wrench needs regular calibration, reliant upon the regularity, grade, and usage over time. By learning when to regulate the torque wrenches, one would be capable of accurate performance every time and achieve steadfast concluding effects.

Where Do You Calibrate Torque Wrench?

The best place to get a torque wrench regulated is at a torque calibration workshop that is proficient in controlling any torque device, even torque multipliers, with up to 35,000 pound-feet (lb. ft.) capabilities and torque transducers that can amount up to 20,000 lb. ft. of torque.

Can You Over Tighten With Torque Wrench?

There are dissimilar types of torque wrenches, from the humblest to the most refined, all of which are intended to measure the torque worth: the amount of force smeared while fastening a nut or screw. They’re all gears designed to fasten correctly and stop over-tightening or under-tightening a bolt.

How Do I Know If My Torque Is Untying?

Merely take a bolt or bolt that is stiffened and start to untie it gradually. Be acute and record the precise torque reading when the fastener becomes unattached. The torque value essential to loosen the fastener will be the estimated force employed on the joint.

What To Look For In A Dirt Bike Torque Wrench?

In my view, these are the utmost significant things to look for:

It covers from 3 to 15 foot-pounds of torque, which is the most mutual variety for bolts on a dirt bike. Please don’t get a torque wrench that jolts at 20 foot pounds like a regular torque wrench, or it won’t be much good on a dirt bike. Instead, you require one that can degree the low torque locations obligatory for a dirt bike. While no bolt on dirt bike necessities to be tightened only to 2 foot pounds, it’s good to have one that twitches small because most torque wrenches are most correct in the mid of their range.

> Digital readout

1/4, 3/8, or 1/2″ drive optimal is problematic. If you can only purchase one, get a 1/4″ as it’ll work for the most significant rods on a dirt bike. If you can purchase two wrenches, add the 3/4″. Backlit data so you can simply see the dimension even when functioning in a blurred garage setting. Measurement to the tenth of a pound or better. Your handbook possibly says things like “tighten the bolt to 5.1 ft./lbs.” It would be best if you had a torque wrench to do that.

Something that will halt adjusted for an extended time and endure, to be precise. The inexpensive “beam and pointer” torque wrenches can get twisted and wrecked. Not all torque wrenches are shaped equivalent. They were not accurate at all.

One prime you’ll make is between a digital torque wrench and an equivalent torque wrench. In my view, lean toward the digital torque wrench if you can pay for one, but often they can be very exclusive. The advantage of the digital torque wrench is pleasant, clear, and exact information. Besides, the scale is more precise, from light to weighty. Another thing to look for is to ensure that the torque wrench will display the poundage you need on the nimbler weight bolts.

Many torque wrenches are made for weighty truck tires and other hefty apparatus and won’t display an exact measurement for between 10 and 15 pounds. The last thing you’ll need to know in selecting a torque wrench is to make sure it is the accurate size. Finally, you must ensure it will work with the bolts you usually need on a dirt bike. Many of those bolts are much slighter than the bolts that you would find on a truck engine.

> Don’t Go Low-priced

Don’t go cheap lest you want to check your good luck. If your torque wrench doesn’t work appropriately, you may end up cropping off a bolt on your dirt bike, wasting time and money. If you want good fortune, go with the Bikemaster 1/4″ digital torque wrench.

Conclusion

Whatsoever torque wrench you select, be certain you do get one. It truly is the value of the investment. Once you acquire your torque wrench, don’t be indolent and flop to practice it. Every time you need to tighten a screw on your bike, look it up in the guidebook to ensure you’re tightening it to the exact extent. Finally, you’ll learn the most mutual numbers. Finally, you’ll be happy to do work well done.

![11 Best Dirt Bike Degreaser [Dirt Bike Cleaning Kit] 11 Best Dirt Bike Degreaser [Dirt Bike Cleaning Kit]](https://dirtbikecoach.com/wp-content/uploads/2022/09/Untitled-design-211x150.png)

![Best Dirt Bike Chain Lubes Of All Time [Expert Opinion] Best Dirt Bike Chain Lubes Of All Time [Expert Opinion]](https://dirtbikecoach.com/wp-content/uploads/2022/08/Best-Dirt-Bike-Chain-Lubes-211x150.png)